The Silicone Carbide Sic Fiber Market is experiencing significant advancements due to innovative manufacturing processes that enhance fiber quality, performance, and cost-efficiency. Known for high tensile strength, thermal stability, chemical resistance, and lightweight properties, silicone carbide fibers are increasingly utilized in aerospace, automotive, electronics, and defense sectors. Advances in production methods have become a key driver of market growth, allowing manufacturers to meet evolving industrial demands with precision-engineered fibers.

One of the most impactful innovations is the use of chemical vapor deposition (CVD), which enables the production of high-purity fibers with controlled mechanical and thermal properties. CVD allows precise layering of materials, resulting in fibers with consistent diameter, uniform composition, and superior performance. Polymer impregnation and pyrolysis techniques further enhance mechanical strength and thermal resistance. These innovations ensure that fibers are suitable for high-stress applications, including engine components, turbine blades, and ballistic armor.

Automated and digital manufacturing processes are also transforming the market. Computer-controlled fiber production ensures consistent quality while minimizing human error and material waste. Simulation software and computer-aided design (CAD) tools enable engineers to predict fiber behavior under various operating conditions, optimizing production parameters for maximum efficiency and reliability. The Silicone Carbide Sic Fiber Market Research highlights that such process innovations are essential for scaling production without compromising performance.

Integration of fiber-reinforced composites has expanded with these technological advancements. Modern manufacturing methods allow precise alignment of fibers within resin matrices, improving mechanical performance, thermal stability, and weight reduction. Aerospace and automotive manufacturers benefit from lighter, more durable components that enhance fuel efficiency, structural integrity, and safety. Similarly, electronics applications rely on precise manufacturing to produce thermally stable components for high-power devices and semiconductors.

Sustainability is a growing focus in manufacturing innovations. Energy-efficient furnaces, optimized chemical usage, and waste recycling reduce environmental impact while lowering operational costs. Manufacturers that adopt eco-friendly practices can comply with global environmental regulations and meet client expectations in sustainable industrial practices. Green manufacturing also enhances brand value and positions companies competitively in environmentally conscious regions.

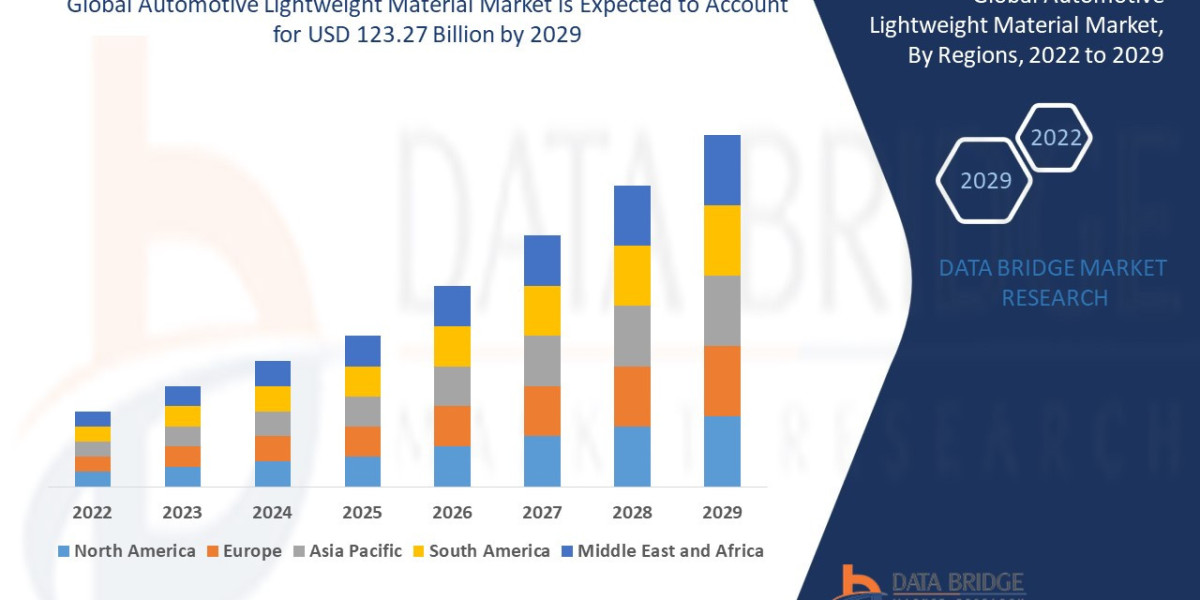

Regional adoption of advanced manufacturing varies. North America and Europe lead in process innovation due to high-value aerospace, defense, and electronics markets. Asia-Pacific is rapidly embracing automation and precision engineering to meet the increasing demand in automotive and electronics sectors. Emerging markets in Latin America and the Middle East are gradually integrating advanced production techniques, creating new opportunities for expansion.

In conclusion, innovations in manufacturing processes are pivotal to the Silicone Carbide Sic Fiber Market. Techniques such as chemical vapor deposition, polymer impregnation, automated production, and digital design improve fiber performance, consistency, and sustainability. As industries demand lightweight, durable, and thermally stable materials, manufacturers investing in advanced production processes are likely to achieve market leadership, operational efficiency, and long-term growth.