Browse all products

This change not only elevates the overall appeal but additionally displays positively on the maintenance requirements of your facility. Explore our business solutions and technology to help defend your belongings. See how we assist prospects discover personalized options for his or her project and application challenges. Apart from this, all parts uncovered to open air underneath the influence of reasonably aggressive setting, also needs to be scalded along the perimeters to keep away from appearance of hollow areas and spacing gaps. All inner components of the tank, welded to the shell, bottom or roof, should be scalded alongside the perimeters to avoid look of hollow areas and spacing gaps. Keeping the thickness of metallic structures uncovered to mildly aggressive influence is achieved solely by the use of corrosion allowances. After the work is finished acceptance certificate is signed, which has to be accompanied by certificates for materials used.

Nationwide Services

The incorrect paint will fade faster, trigger structural injury, and even cause your structure to collapse. The working interval of effectiveness for protecting coating must be not lower than 10 years. Protective present goes precisely to those metal areas, where the density of the coating is damaged. It reaches all shadowed areas, gaps, hollow areas, preventing the bare metallic from staining. It must be famous that in the midst of cathodic polarization local and bottom water exhibits sure salt gel that contains insoluble Ca and Mg salts and performs the position of extra coating. For example, penetrating corrosion backside destruction of the tanks, used for oil settling, and circulate strains could result in oil spills that pollute the surroundings. Moreover, there seems the want to replace the tank bottoms already after 5-6 years of operation, which is complicated, contemplating the diameter of the bottom equal to almost 50 m (for vertical metal tank ).

Top Rated Painting Services

It’s a wonderful alternative for industrial tank portray, factories, work areas uncovered to the weather, structural parts, walls, floors and other comparable websites within the office. In terms of cost-effectiveness, an overcoat system could additionally be sufficient for extending service life within the brief term. This isn't an equal substitute for commercial blasting to reveal substrate and ranging from scratch, given the service life of coatings are thought-about proportional to the floor prep concerned. However, an overcoat system is a superb alternative for a quick, relatively low-cost job that can look nice and continue to supply safety.

A Guide to AWWA C210 for Epoxy Coatings & Linings

A Guide to AWWA C210 for Epoxy Coatings & Linings We mix the business's best paint with our passion for element to exceed your expectations. Priming the steel floor is essential for efficient adhesion and rust inhibition. For non-ferrous metals, think about a common metal primer, while for ferrous metals, alkyd primers are often beneficial. Since storage tanks are confined areas, they require the presence of a gap watch.

Safety Precautions

When working with water, fuel, or storage tanks, industrial portray methods must all the time embody a cautious review of the safety precautions to safe the job web site and keep everybody protected. This contains portray contractors and any staff that will work in close by areas. You can use the best coating/paint products in the world, but when the floor is not prepared properly before the applying, premature coating failure and substrate metallic deterioration is inevitable. Bolted and welded steel tank exteriors are vulnerable to corrosion brought on by many outside causes. In all circumstances, as soon as corrosion has started under the tank’s protecting coating, the structural integrity of the vessel could be affected and if not corrected, finally compromise the helpful lifetime of the tank.

2. Technological process of applying the corrosion protection coating:

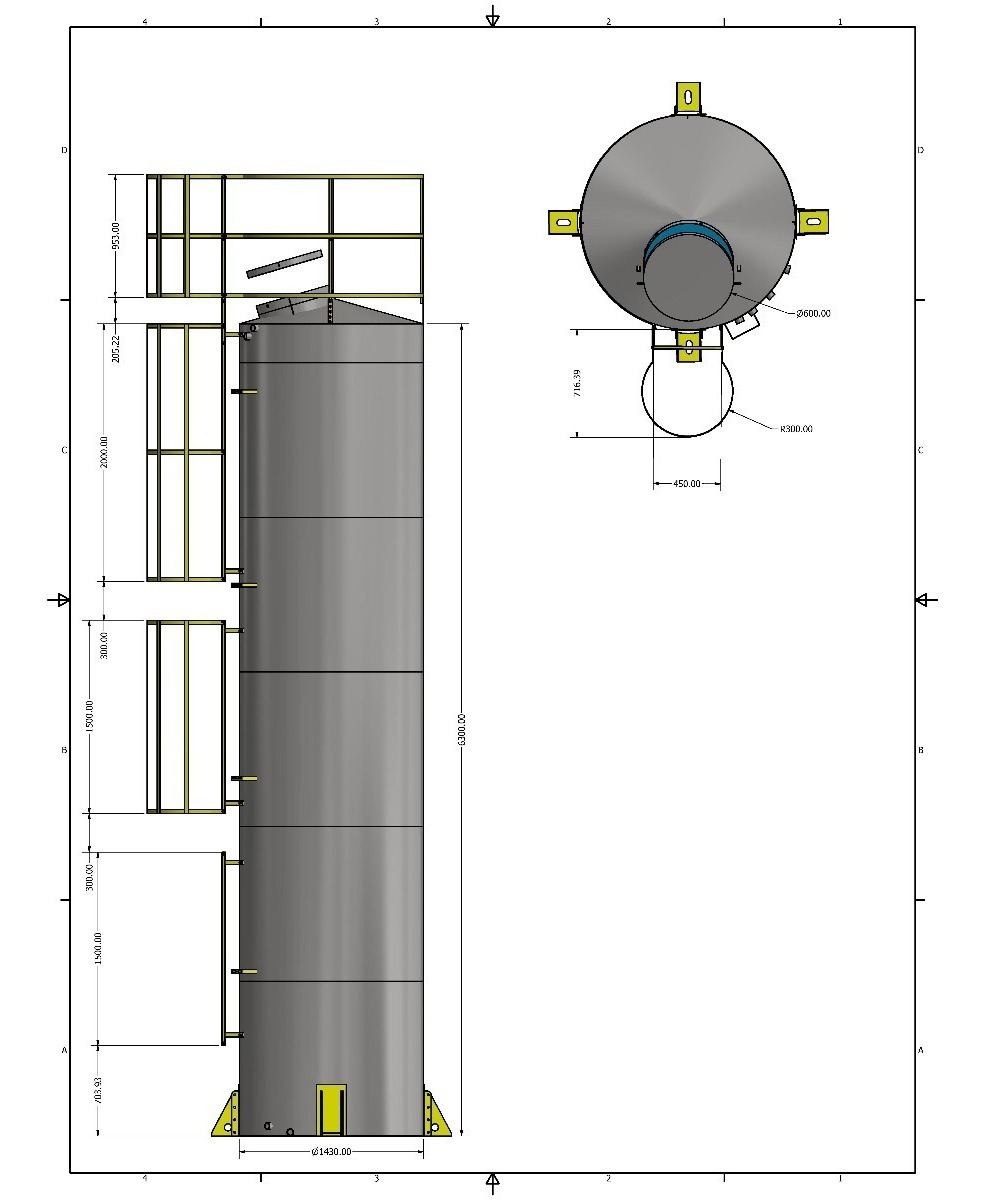

Elevated Tanks on Towers

Additionally, our pedestal design can embody multiple storage levels similar to the designs we routinely provide in the energy trade. Tank Connection's RTP (rolled, tapered panel) tank design is on the market with our prime efficiency coating system for potable water storage, caixa dagua Metalica LIQ Fusion 8000 FBE™. The tank cover is on the market in the same development as the tank or Caixa dagua Metalica with an aluminum geodesic dome. Caldwell is a number one firm in the design and development of pedesphere elevated storage tanks. Our single pedestal pedesphere design makes use of a spherical form, providing increased structural strength and stability. This allows our tanks to be constructed to greater heights, maximizing house utilization, and reducing land footprint.