These crucial chemical compounds play a pivotal role in reducing the coefficient of friction (CoF) in polymers, primarily plastics, thereby enhancing their processability, handling, and end-use performance.

Why are Slip Additives Indispensable?

At their core, slip additives, typically fatty amides like oleamide and erucamide, or polysiloxanes and waxes, migrate to the surface of a plastic film or molded part. This creates a thin, lubricating layer that allows surfaces to slide more easily against each other or against processing equipment. This seemingly simple function yields significant benefits:

- Improved Processability: Reduced friction during extrusion, blowing, and molding processes enables higher line speeds and fewer production issues like sticking or tearing, leading to increased throughput and cost efficiency for manufacturers.

- Enhanced End-Product Performance: For applications like packaging films, slip additives ensure smooth unwinding of rolls, easy bag separation, and improved printability and sealability. In consumer goods and automotive parts, they contribute to better tactile feel, reduced scratching, and improved assembly.

- Cost-Effectiveness: Slip additives offer a cost-effective solution to friction-related challenges, requiring only minimal addition levels (often 1000 ppm or less) to achieve desired results.

Market Dynamics and Key Drivers

The burgeoning demand from the packaging industry is a primary driver for the slip additives market. With increasing global consumption of packaged goods, particularly in the food & beverage and e-commerce sectors, the need for efficient and high-performance packaging materials is escalating. Packaging films alone accounted for a substantial market share, around 72%, in 2023.

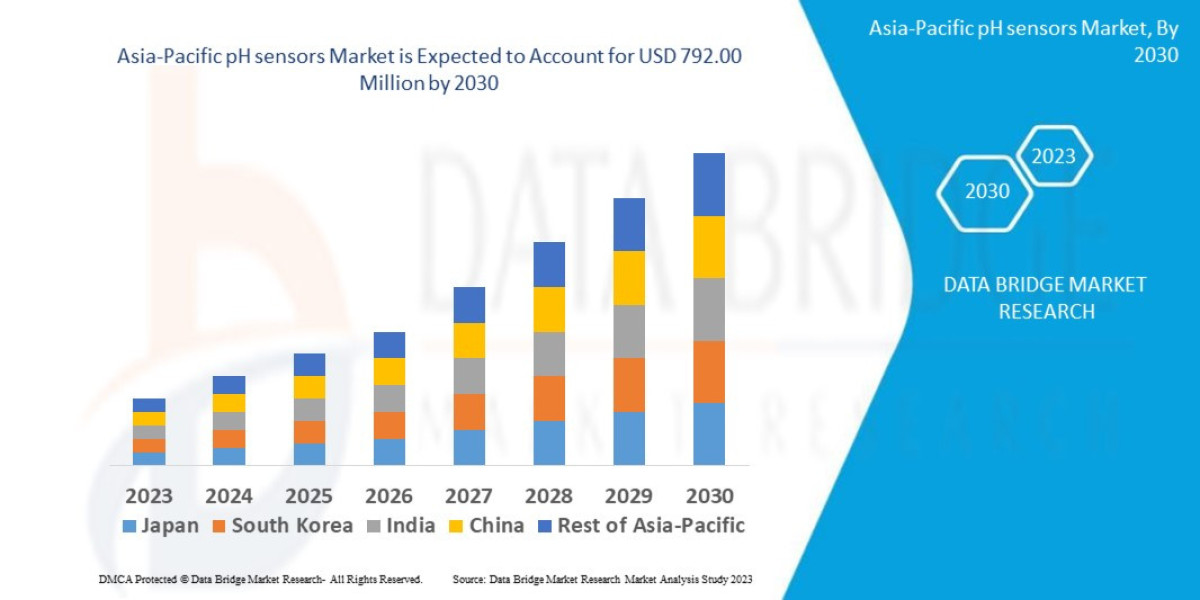

Beyond packaging, other key applications include agricultural films, automotive components, and various consumer goods. Rapid industrialization and urbanization in emerging economies, notably in the Asia-Pacific region, are significantly contributing to market expansion. Asia-Pacific dominated the market in 2023, driven by the presence of large plastic manufacturers and growing demand from end-use sectors in countries like China and India.

Emerging Trends and Challenges

The market is witnessing a notable shift towards sustainable and bio-based slip additives. Growing environmental concerns and stringent regulations on plastic usage are pushing manufacturers to invest in R&D for plant-based and biodegradable alternatives derived from renewable sources. This trend aligns with the broader industry focus on reducing carbon footprints and adopting greener manufacturing processes.

However, the market also faces challenges such as raw material price volatility and health and safety concerns associated with certain conventional additives. Nonetheless, continuous technological advancements, including the development of non-migratory and multi-functional slip additives, are creating new opportunities and enhancing product performance.

In conclusion, the slip additives market is a vital component of the plastics and packaging industries, enabling efficient production and superior product quality. Its future growth will be shaped by the increasing demand for high-performance materials and the growing imperative for sustainable solutions.

Get Sample Report: https://www.theinsightpartners.com/sample/TIPRE00010697

Author's Bio:

Nilesh Shinde

Senior Market Research expert at The Insight Partners