Laser technology has transformed the way industries approach surface preparation, rust removal, and metal restoration. Among the most advanced applications, laser cleaning metal stands out as a reliable, eco-friendly, and cost-effective solution. Mart Laser provides cutting-edge laser cleaning machines designed to meet the demands of modern industries, offering unmatched precision and efficiency.

Unlike traditional cleaning methods such as sandblasting or chemical treatments, laser cleaning relies on focused laser beams that remove rust, paint, or contaminants from metal surfaces without damaging the underlying material. This technology ensures that metal surfaces are restored to their original state with minimal effort and maximum control. Mart Laser specializes in delivering systems that are not only powerful but also user-friendly, making them suitable for a wide range of industrial applications.

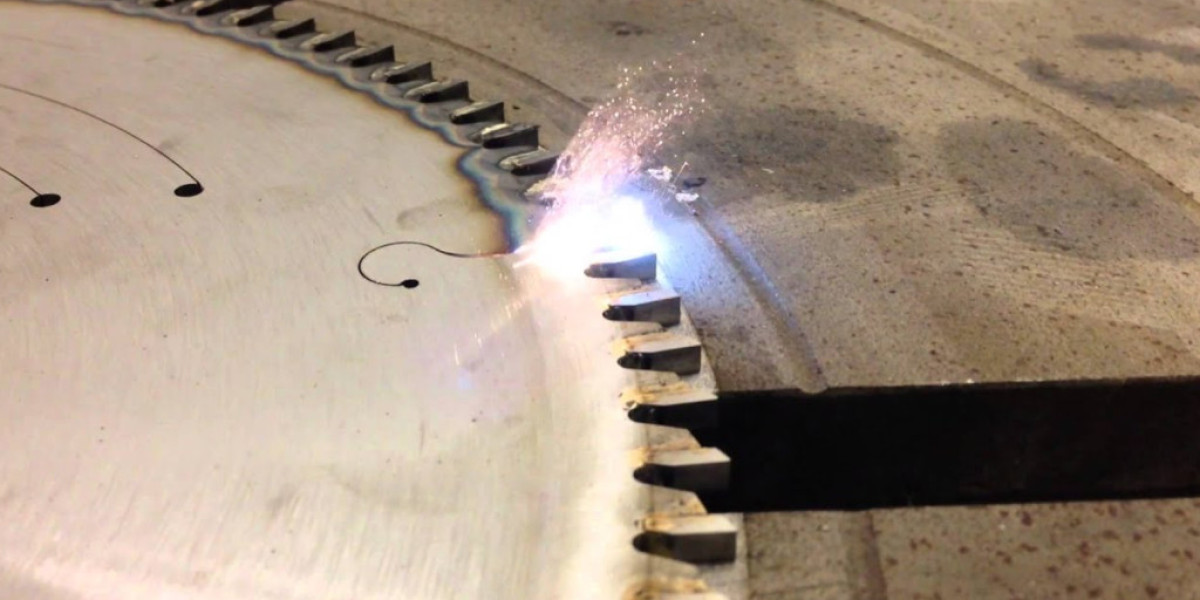

Industries such as automotive, aerospace, shipbuilding, and manufacturing rely heavily on clean metal surfaces for both aesthetics and functionality. Whether it’s removing rust from car parts, cleaning molds in production facilities, or preparing surfaces for welding, Mart Laser’s laser cleaning metal machines ensure consistent results. By eliminating the need for harsh chemicals or abrasive materials, these machines provide a safer workplace while also reducing environmental impact.

One of the key strengths of Mart Laser’s technology is precision. The laser cleaning process can be adjusted to remove specific layers of contamination without affecting the integrity of the base metal. This makes it ideal for delicate projects as well as large-scale industrial cleaning tasks. Additionally, Mart Laser machines are designed for long-term performance, delivering reliability and efficiency that businesses can count on.

Another major advantage is cost savings. Traditional cleaning often requires consumables like sand, chemicals, or protective gear, driving up long-term expenses. With Mart Laser’s laser cleaning metal solutions, the process is non-contact and does not require consumables, significantly lowering operational costs. Over time, businesses can achieve faster ROI by adopting laser cleaning technology.

Mart Laser continues to innovate by developing machines with advanced controls, portability, and energy efficiency. Whether businesses need compact solutions for smaller components or high-power systems for heavy-duty cleaning, Mart Laser offers customizable options to meet unique requirements.

By choosing Mart Laser, companies gain more than just equipment – they gain a partner committed to delivering reliable technology, technical support, and long-term value. The combination of eco-friendly operation, precise performance, and reduced costs positions Mart Laser as a leader in the laser cleaning metal industry.

In conclusion, the future of industrial metal cleaning lies in laser technology, and Mart Laser is at the forefront of this transformation. For businesses looking to improve efficiency, reduce environmental impact, and achieve flawless results, Mart Laser provides the perfect solution.