Introduction

Producing high-quality coffee requires precision and efficiency at every stage. Coffee production equipment is essential for farms, roasteries, and specialty coffee labs to process beans from cherry to cup. From pulping, drying, and hulling to roasting and packaging, each stage demands reliable machinery. Using professional coffee production equipment ensures consistency, reduces waste, and enhances flavor profiling. For coffee professionals, having the right tools is key to delivering premium specialty coffee that meets the expectations of discerning customers globally.

Understanding Coffee Production Equipment

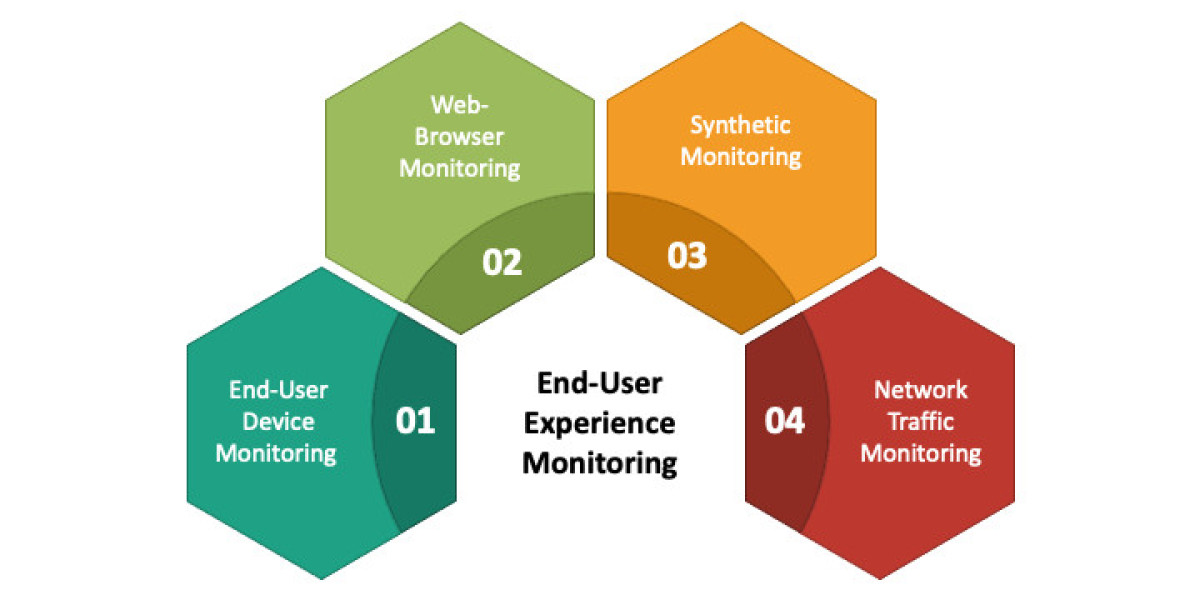

Coffee production equipment encompasses all machinery and tools used in the coffee supply chain. This includes pulpers, fermenters, drying beds, hulling machines, graders, sample roasters, grinders, and lab instruments for quality assessment. Professionals rely on coffee production equipment to monitor moisture levels, detect defects, and ensure beans meet high-quality standards. Proper use of this equipment supports reproducibility, operational efficiency, and innovation in coffee production, enabling farms, cafés, and roasteries to consistently produce specialty coffee.

Types of Coffee Production Equipment

A wide range of coffee production equipment exists to serve different stages of coffee processing:

Pulping Machines: Remove the cherry’s outer layer.

Fermentation Tanks: Facilitate controlled fermentation for flavor development.

Drying Equipment: Includes drying beds and mechanical dryers to reduce moisture content.

Hulling Machines: Remove parchment and husk from beans.

Grading and Sorting Machines: Ensure uniform size and remove defective beans.

Roasters and Lab Tools: Evaluate aroma, flavor, and roast profiles.

Each piece of coffee production equipment plays a vital role in maintaining quality and consistency throughout the coffee production process.

Advantages of Using Coffee Production Equipment

Investing in coffee production equipment offers numerous benefits:

Consistency: Ensures uniform roasting, drying, and grading.

Efficiency: Speeds up processing while reducing labor and errors.

Quality Control: Monitors moisture, defects, and flavor profiles at every stage.

Innovation: Supports experimentation with new processing methods and blends.

By integrating coffee production equipment into operations, farms, roasteries, and labs can maintain high standards while minimizing waste and improving workflow.

Specialty Coffee and Coffee Production Equipment

Producing specialty coffee requires careful handling from cherry to cup. Coffee production equipment allows professionals to maintain consistent quality while highlighting the unique characteristics of each bean. Lab tools, sample roasters, and grinders enable precise flavor profiling and reproducibility. For cafés, labs, and roasteries, coffee production equipment ensures that every batch delivers exceptional aroma, taste, and body, meeting customer expectations and maintaining a competitive edge in the specialty coffee industry.

Enhancing Efficiency with Coffee Production Equipment

Operational efficiency is key for large and small-scale coffee producers. Properly integrated coffee production equipment allows for faster processing without sacrificing quality. Automation in pulping, drying, and grading reduces labor-intensive tasks while maintaining consistency. Using coffee production equipment effectively ensures smooth workflow, minimizes human error, and allows producers to meet market demand efficiently, all while preserving the quality and flavor of the coffee beans.

Integrating Lab Tools with Coffee Production Equipment

Lab instruments complement coffee production equipment by providing detailed data on moisture content, roast curves, and flavor profiles. Using these tools together helps professionals monitor every stage of production and ensures reproducibility. Integration of lab equipment with coffee production equipment allows for innovation, quality assurance, and the creation of signature blends, supporting both research and development in specialty coffee production.

Sustainable Practices in Coffee Production

Sustainability is increasingly important in coffee production. Using coffee production equipment responsibly reduces waste, energy consumption, and environmental impact. Precision tools and small-batch processing help minimize overproduction and conserve resources. By integrating sustainable practices with coffee production equipment, farms, cafés, and roasteries can maintain high-quality standards while supporting eco-friendly operations and meeting consumer demand for ethically produced coffee.

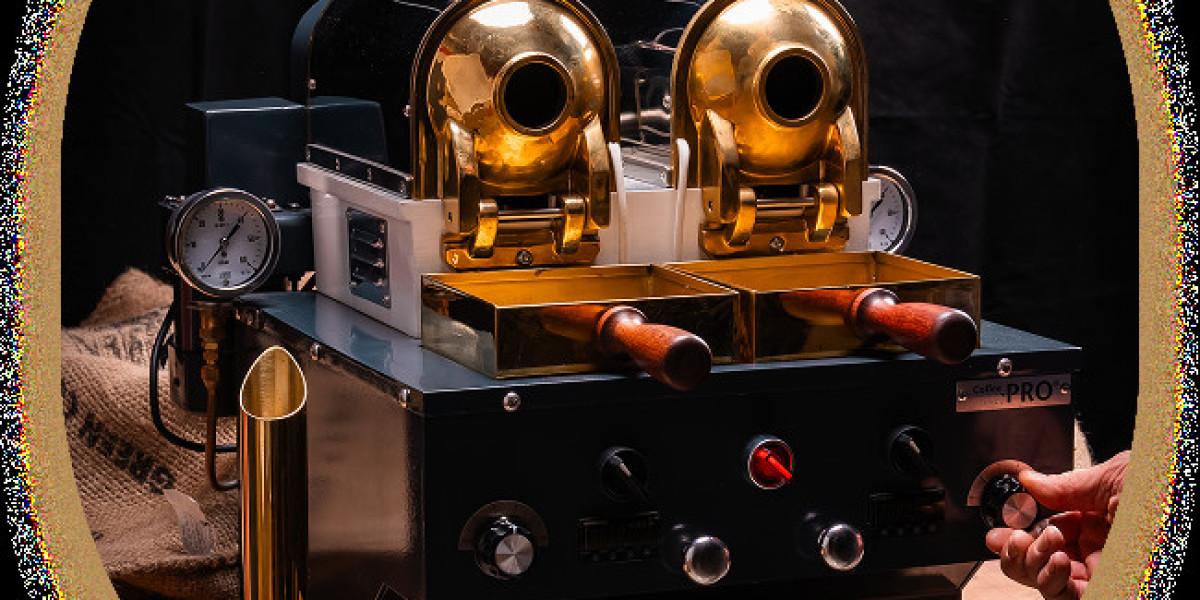

Why Choose Coffee Pro Direct for Coffee Production Equipment?

Selecting a reliable supplier is essential when investing in coffee production equipment. Coffee Pro Direct offers professional-grade machinery and lab tools designed for precision, durability, and efficiency. Whether you need pulpers, hulling machines, mechanical dryers, sample roasters, or lab instruments, Coffee Pro Direct ensures access to high-quality equipment and technical support, helping businesses maintain consistent coffee quality, improve workflow, and innovate in specialty coffee production.

Our Business Location

Coffee Pro Direct is located at 21st Floor, CMA Building, 64 Connaught Road Central, Hong Kong, providing global access to premium coffee production equipment. Partnering with Coffee Pro Direct guarantees reliable equipment, expert guidance, and ongoing support, enabling cafés, roasteries, and labs to produce consistent, high-quality coffee.

Training and Skill Development with Coffee Production Equipment

Proper training is essential to maximize the potential of coffee production equipment. Professionals learn to optimize processing, roasting, and lab testing for reproducibility and flavor accuracy. Using lab instruments alongside production machinery helps staff understand bean behavior and maintain quality standards. Training ensures that cafés, roasteries, and labs can efficiently use coffee production equipment to produce specialty coffee with consistent taste, aroma, and quality.

Innovations in Coffee Production Equipment

Modern coffee production equipment incorporates advanced technology for precise control, automation, and monitoring. Digital controls, automated dryers, smart graders, and integrated lab tools allow professionals to track roast curves, moisture levels, and flavor profiles. These innovations ensure reproducibility, reduce errors, and support research and development. Investing in advanced coffee production equipment helps farms, roasteries, and labs stay competitive and deliver exceptional specialty coffee consistently.

Preventive Maintenance of Coffee Production Equipment

Maintaining coffee production equipment is crucial for performance, reliability, and longevity. Regular cleaning, calibration, and preventive care prevent issues such as uneven drying, defective hulling, or inconsistent roasting. Monitoring equipment with lab tools helps detect early signs of wear or malfunction. Proper maintenance ensures cafés, roasteries, and labs can operate efficiently, reduce downtime, and maintain consistent coffee quality.

Research and Development Opportunities

Coffee production equipment supports R&D in specialty coffee by allowing small-batch testing, experimental roasting, and precise flavor profiling. Lab tools integrated with production equipment enable detailed analysis of aroma, body, and acidity. Using R&D data, professionals can optimize processing methods, develop new blends, and maintain reproducibility. Combining innovation with reliable coffee production equipment ensures high-quality specialty coffee production and supports competitive growth in the market.

Conclusion

Investing in high-quality coffee production equipment is essential for farms, roasteries, and labs seeking precision, consistency, and innovation. From pulping and drying to hulling, grading, roasting, and lab testing, every stage benefits from professional-grade machinery. Partnering with Coffee Pro Direct ensures reliable equipment, expert guidance, and ongoing support, allowing businesses to maintain operational efficiency, reproducibility, and deliver premium specialty coffee consistently.

FAQs

What is coffee production equipment used for?

Coffee production equipment is used to process coffee beans from cherry to roasted coffee, including pulping, drying, hulling, grading, and lab testing.

Can small cafés benefit from coffee production equipment?

Yes, small cafés can use coffee production equipment for small-batch roasting, quality control, and flavor profiling to maintain specialty coffee standards.

What types of coffee production equipment are essential?

Essential coffee production equipment includes pulpers, fermenters, mechanical dryers, hulling machines, graders, sample roasters, and lab instruments.

Why is coffee production equipment important for specialty coffee?

It ensures precision, reproducibility, and quality control, producing consistent flavor, aroma, and body in every batch of coffee.