The logistics system of the world is the circulatory systems of the global economy It is a complicated interconnected network of moving gear that produces and receives everything from specialty medical items to food and groceries as a routine service. Meanwhile, the lack of app modernization in Logistics industry has been afflicted with inefficiencies for decades to the point we see delayed shipment, inaccurate inventories, outrageous freight prices and customers continuously disappointed with unmet expectations for faster and transparent delivery. It is an ever-changing, uncertain environment with incredibly high customer expectations. Sadly, manual processes cannot meet those expectations alone and can create workflow bottlenecks, confusing visibility and disruption risks.

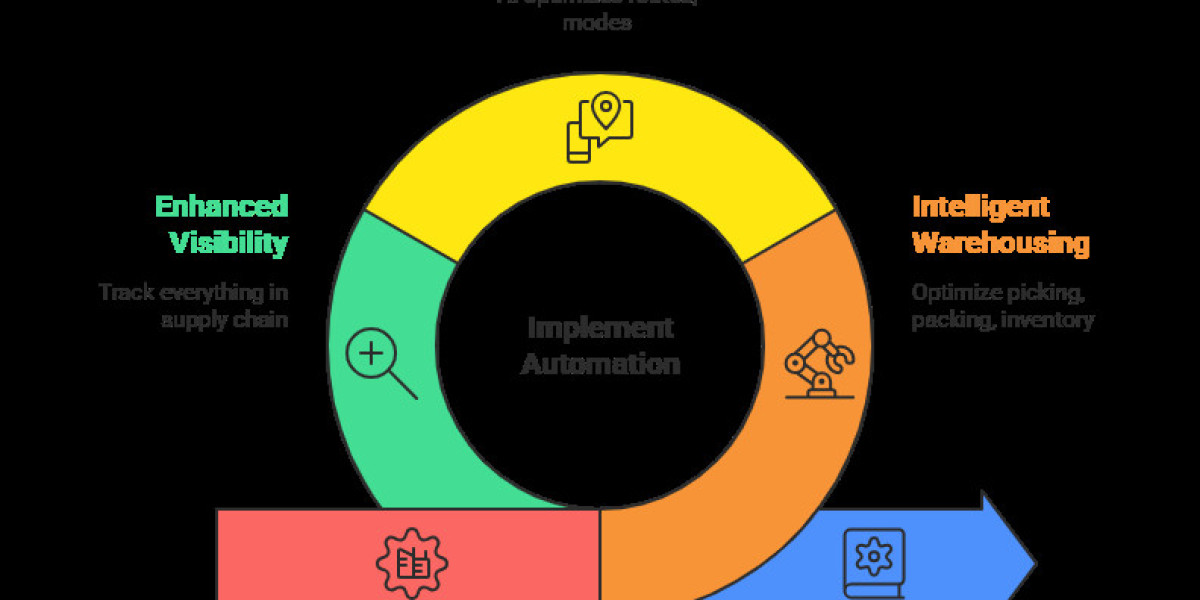

The solution to these problems that have existed for over a century is a single disruptive force: automation. As we discussed earlier in this blog, automation has become an important operational choice for any business: it is always more than downsizing labour cost. Automation emerged relatively new, almost primitive as an arm to supply chain visibility optimization: logistics automation systems provide artificial-intelligence enabled, cognitive-thinking, decision support systems as the foundation of & supply chain and logistics operations. By adopting AI-enabled solutions and additional digital solutions in logistics, businesses are not just creating efficiencies, they are evolving/inventing themselves into a time-perfect business space for digital operations.

This blog will explore how automation serves as the central nervous system of a high-performing supply chain, driving value from the warehouse to the customer's

The High Stakes of Inefficiency in Logistics

The cost of still using obsolete, siloed processes in logistics is vast, diverse, and multi-dimensional. Dispatchers can, and will, potentially spend hours using the telephone and using email to being together communication with carriers and customers thus creating opportunities for miscommunications or delays. Warehouse workers can walk literally miles back and forth picking multiple items for, for example a furniture order (entirely on a piece of paper!) Distinguishing order numbers, not to mention fatigue can lead to picking errors. Similarly, planners use spreadsheets to estimate forecast demand and plan routes but they do not have a way to account for real world issues like traffic jams, weather changes, or simply changes to consumer behaviour that can impact quantities for the entire industry (fads, shortages, etc).

That's not to say that all these activities are inherently negative regardless of form, it's just to say that when you look at all of the volume, all these failures add up to costly implications for the company. The Council of Supply Chain Management Professionals (CSCMP) notes logistics spending is now somewhat spillover topic of a product's retail price. Pain points include:

High Operational Expenses: Labor-intensive processes in warehousing and transportation are the largest component of logistics spend.

Inventory Blind Spots: Companies find themselves with lost sales due to stockouts or excess inventory that use working capital and adds cost to holding inventory, absent of incoming or a customer order when detracting working capital.

Poor Asset Utilization: When planning is done using manual processes, we often witness trucks running half empty or routed in a sub-optimal manner that wastes both fuel and space.

Lack of Resilience: Several major events could disrupt normal operation-a port closure or demand spike.

We saw this during the pandemic, with labour shortages and sudden demand spikes causing delays in even the best plans manually developed. Manual systems DON"T have the flexibility to move shipments and assign people and resources based on available capacity-even transport fleets! This scenario creates a burning platform for companies to seek out digital alternatives and better methods to maximize operations efficiency and create a more agile and responsive supply chain.

The Automated Logistics Ecosystem: From Siloes to Synergy

Automation in logistics is not a single technology but a synergistic ecosystem of solutions that interact with and improve every link of the supply chain. This practice of integration, allows companies and their suppliers to truly make supply chain work through technology, and not as independent vendors.

Core Areas Transformed by Automation

1. Intelligent Warehousing:

The warehouse more than a cost centre, it is now a strategic asset in supply chain and process efficiency. Automated Storage and Retrieval Systems (ASRS), and autonomous mobile robots (AMRs) work alongside people to optimize picking and packing and save walk time. We can reduce walk time and mistakes to the extent of up to 70%! IoT sensors provide real-time visibility of inventory levels in the warehouse and through re-trigger orders automatically when stock runs low. This approach reduces costly manual cycle counts, ensures inventory data is always consistent and gives logistics managers instant feedback while tackling one of the greatest pains in logistics.

2. Smarter Transportation Management:

This is where ai-powered logistics solutions come into their own. Optimizing routing and modes of transportation is typically limited to static analytical comparisons. AI complete with historical shipping times, real-time traffic data, weather data, carrier performance, and fuel prices allows you to optimize routes and modes on the fly. It not only determines the shortest route, but the most efficient, cost effective and reliable route for each shipment. Further, automation allows you to streamline freight auditing and payment to eliminate manual data entry and will deliver an accurate bill.

3. Enhanced Visibility and Predictive Analytics

Today's automation platforms are able to give a single view of the entire supply chain. The idea is to have tracked everything during every phase from when an order is placed until its final delivery. Ultimately, customers will appreciate the real-time visibility because it enables the company to provide accurate ETAs while they manage exceptions proactively. In addition, AI/predictive analytics will show potential delays and demand changes, as well as equipment maintenance, and the focus will stop being on reactive management or fighting fires.