Pharmaceutical Hot Melt Extrusion Market: Revolutionizing Drug Formulation and Delivery

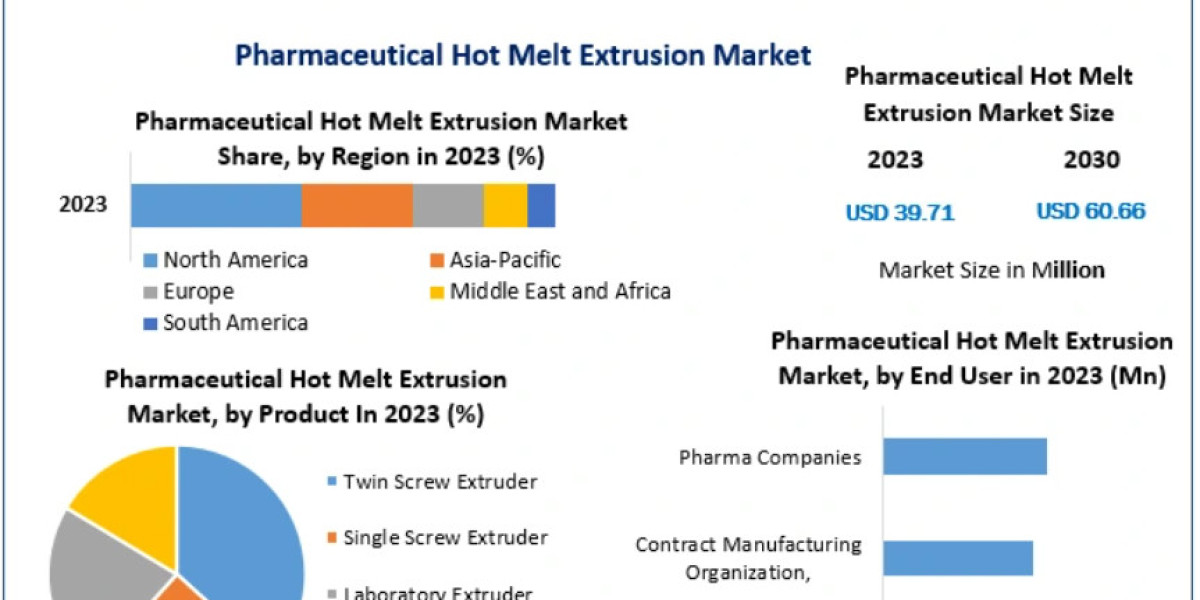

The Pharmaceutical Hot Melt Extrusion (HME) Market was valued at USD 39.71 Million in 2023 and is projected to grow at a CAGR of 6.24%, reaching approximately USD 60.66 Million by 2030. HME is emerging as a transformative technology in pharmaceutical manufacturing, enabling the development of novel drug formulations with enhanced bioavailability and controlled-release properties.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/37193/

Overview of Hot Melt Extrusion in Pharmaceuticals

Hot melt extrusion is a process where polymers and active pharmaceutical ingredients (APIs) are melted under heat and pressure and forced through an orifice to create a continuous, uniform product. While traditionally applied in plastics, rubber, and food industries, HME has gained significant traction in healthcare for producing solid dosage forms, transdermal patches, and drug-eluting implants. Its ability to improve drug solubility and bioavailability has positioned HME as a critical technology for addressing the challenges of poorly soluble APIs.

Market Drivers

Several factors are driving the growth of pharmaceutical HME:

Increasing Number of Novel Drugs: New drug candidates with challenging solubility and bioavailability issues require advanced manufacturing processes like HME.

Regulatory Acceptance: HME aligns with the FDA’s Process Analytical Technology (PAT) initiative, promoting continuous manufacturing and quality assurance in pharmaceutical production.

Flexibility and Efficiency: HME allows easy modification of screw elements, die plates, and extruder designs, enabling precise formulation adjustments and rapid development of customized dosage forms.

Strategic Industry Focus: Manufacturers are emphasizing technological innovation, competitive pricing, mergers, and acquisitions to expand their market share.

Market Segmentation

By Product Type:

Twin Screw Extruder (TSE): Widely used for solid dosage forms, TSE enables both distributive and dispersive mixing and is the most preferred technology for HME.

Single Screw Extruder

Laboratory Extruder

RAM Extruder

By End User:

Research Laboratories

Contract Manufacturing Organizations (CMOs)

Pharmaceutical Companies

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/37193/

Regional Insights

North America: Dominates the market due to early adoption of HME in drug manufacturing and extensive integration in Current Good Manufacturing Practice (cGMP) standards.

Europe: The second-largest market, driven by high demand for innovative drug formulations and robust pharmaceutical infrastructure.

Asia Pacific: Rapidly growing market, supported by increasing pharmaceutical R&D activities and expansion of CMOs.

Latin America & Middle East & Africa: Emerging markets benefiting from growing healthcare investments and pharmaceutical manufacturing initiatives.

Key Players

The market features a mix of global leaders and specialized technology providers, including:

Baker Perkins Ltd.

Coperion GmbH

Gabler GmbH & Co. KG

Milacron Holdings Corp.

Leistritz Advanced Technologies Corp.

Thermo Fisher Scientific, Inc.

Xtrutech Ltd.

Catalent’s OptiMelt

AbbVie

Foster

Midas Pharma

PMC Isochem

Pensatech Pharma GmbH

PozLab

Green Ridge Consulting

PriviLS LLP

These companies focus on continuous innovation, customized solutions, and market expansion, driving the global adoption of HME in pharmaceutical manufacturing.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/37193/

Market Outlook

The Pharmaceutical Hot Melt Extrusion market is set for steady growth as the demand for advanced drug delivery systems increases. Its advantages in enhancing bioavailability, ensuring consistent dosage forms, and enabling novel therapeutic applications make HME a key technology for the pharmaceutical industry. With ongoing technological advancements and regulatory support, HME is expected to redefine drug formulation and manufacturing practices globally.