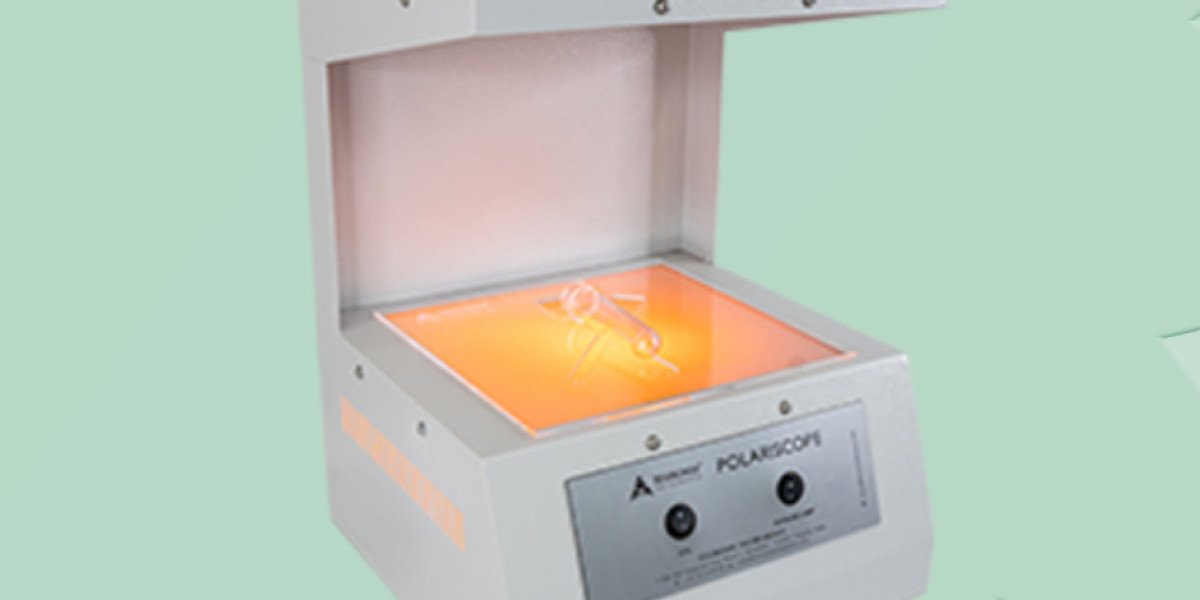

When producing a product, reliability and precision are key to its quality. The Polariscope strain viewer is an excellent tool for detecting stresses in clear materials such as acrylics, metals, plastics, and glass. This advanced optical device effectively reveals invisible stress patterns without causing any damage.

It is used in labs and on the product itself to help manufacturers make sure that their products are consistent, last a long time, and meet strict quality standards. Quality professionals need to know how this tool can help make inspections more accurate and operations run more smoothly, because companies want their products to be more reliable.

Exploring the Role of a Polariscope in Quality Control

A Polariscope strain viewer plays a crucial role in visualizing stress distribution within transparent materials. Using polarized light reveals hidden flaws, birefringence, or stress points that may affect a product’s strength or optical performance. Below are seven significant benefits that highlight why this tool has become indispensable in modern quality inspection and how it helps industries maintain high standards of excellence.

1. Detect Internal Stresses with Precision

One of the best things about a Polariscope strain viewer is how well it can show stresses inside a material. When it comes to materials used for lenses, containers, or structural parts, even small changes in stress can make things break. The Polariscope shows these stresses as colorful fringe patterns, which help inspectors find weak spots before they get worse and become major problems. This feature makes sure that only materials with the best structural integrity move on to the next step in the production process.

2. Enhance Product Reliability and Longevity

Manufacturers can take steps to make materials more stable by finding stress concentrations early on. A product that doesn't have any internal strain works better when it's under pressure and doesn't change shape over time. Using a Polariscope strain viewer not only helps find problems before they happen, but it also makes products last longer. This means better dependability and customer trust in fields like automotive, packaging, and medical devices.

3. Reduce Rejection Rates and Production Costs

Quality defects often result in high rejection rates, rework, and wastage, all of which increase production costs. A Polariscope strain viewer helps minimize these issues by detecting problems before materials are processed further. When used as part of a regular inspection routine, it helps reduce the occurrence of defective batches, allowing manufacturers to save both time and resources. This proactive approach to quality control ensures higher productivity and greater cost efficiency.

4. Support Compliance with Industry Standards

A lot of fields have strict rules about quality and safety that needs materials to be stress-tested in great detail. Using a Polariscope strain viewer helps businesses follow these rules by giving them solid visual proof that their products are stress-free. Optical stress standards help build trust and make sure products meet quality standards around the world, whether they are used for electronics or pharmaceutical packaging.

5. Improve Manufacturing Processes Through Visual Feedback

A Polariscope provides instant visual feedback that helps engineers and quality inspectors refine their manufacturing processes. By observing the stress distribution, they can adjust molding pressures, cooling rates, or annealing times to reduce internal strain. This continuous improvement approach enhances process efficiency and reduces variability between production batches. Over time, such insights lead to optimized operations and consistent product performance.

6. Enable Non-Destructive Testing for Greater Efficiency

One of the major strengths of a Polariscope strain viewer lies in its non-destructive testing capability. Instead of cutting, bending, or altering a sample, it allows for inspection without causing damage. This feature is particularly beneficial when dealing with high-value components or delicate materials. Non-destructive testing not only preserves sample integrity but also speeds up the inspection process, enabling faster decision-making in production environments.

7. Integrate Easily into Quality Assurance Workflows

Modern quality inspection processes demand tools that are easy to integrate into existing workflows. A Polariscope strain viewer fits seamlessly into both laboratory and production settings. Its user-friendly operation allows technicians to conduct tests quickly without extensive training. Many advanced models, such as those provided by Testronix Instruments, feature ergonomic designs and adjustable viewing angles that make them practical for routine use. With such integration, organizations can achieve consistent quality assessment and maintain a smooth inspection workflow.

Driving Quality Excellence with Reliable Stress Analysis Tools

The use of a Polariscope strain viewer empowers manufacturers to achieve a deeper understanding of material behavior and internal stress patterns. Its role extends beyond mere inspection; it acts as a diagnostic tool that drives quality improvement across every production stage. By combining optical precision, non-destructive testing, and visual clarity, this instrument helps industries uphold product integrity while optimizing operational efficiency. Brands like Testronix Instruments continue to innovate in this space, offering high-quality strain viewers that support modern quality control needs.