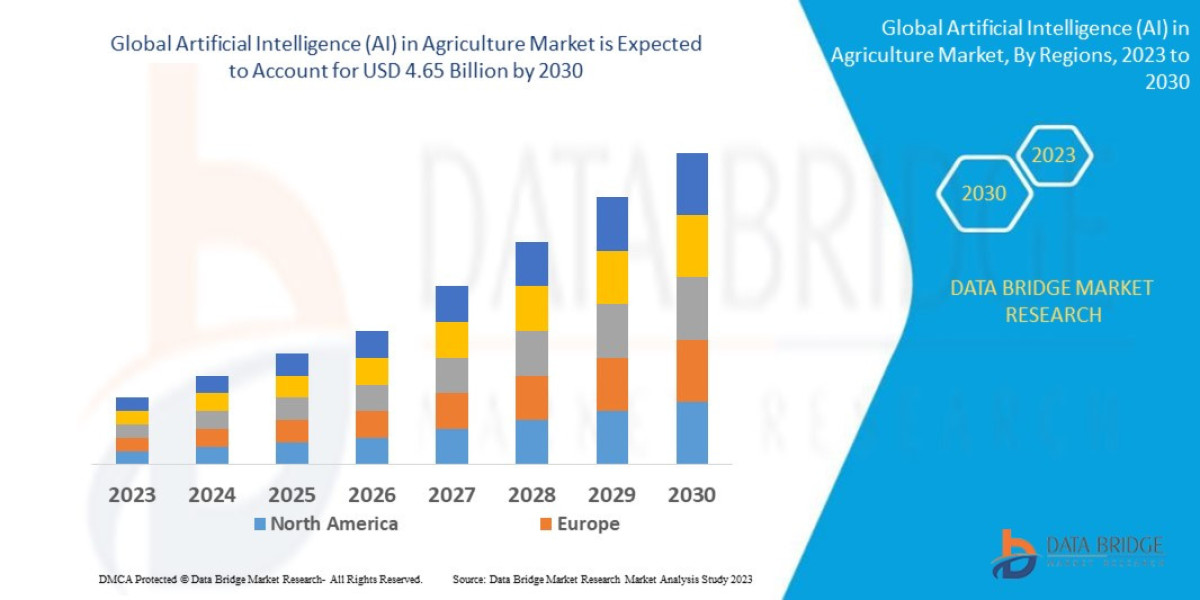

The Aircraft Floor Panels Market is estimated to be valued at USD 352.2 million in 2025 and is projected to reach USD 667.4 million by 2035, registering a compound annual growth rate (CAGR) of 6.6% over the forecast period.

The Global Aircraft Floor Panels Market is gaining strong traction as aircraft manufacturers increasingly focus on lightweight, durable, and fire-resistant interior materials to enhance fuel efficiency and passenger safety. With rising air traffic, fleet modernization programs, and advancements in composite material technology, the market for aircraft floor panels is expected to witness substantial growth over the coming decade.

Aircraft floor panels, designed to provide structural integrity and support cabin interiors, play a critical role in optimizing aircraft weight and improving overall operational performance.

Get Instant Access for Only $5000 | Don’t Miss This Exclusive Offer!

https://www.futuremarketinsights.com/reports/sample/rep-gb-5349

Market Overview

Aircraft floor panels are integral structural components installed between fuselage frames and floor beams, forming the base of the cabin. These panels must balance strength, lightness, and safety standards, as they support passenger loads, cargo, and cabin furnishings.

The demand for composite-based and honeycomb core floor panels is rising rapidly due to their lightweight properties, high stiffness-to-weight ratio, and corrosion resistance. These features make them ideal for both commercial and military aircraft applications.

Key Market Drivers

- Rising Demand for Lightweight Aircraft Materials

The aviation industry’s ongoing efforts to reduce carbon emissions and fuel consumption have led to greater adoption of lightweight composite floor panels. Replacing traditional aluminum panels with advanced composites significantly reduces aircraft weight, improving fuel efficiency and operational range. - Growth in Air Travel and Fleet Expansion

Increasing passenger traffic and fleet expansion by major airlines are fueling the demand for new aircraft production and replacement of aging interiors. Aircraft OEMs such as Boeing, Airbus, and COMAC are accelerating production rates, directly contributing to market growth. - Stringent Safety and Fire-Resistance Regulations

Aviation authorities like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) enforce strict standards for flammability, smoke density, and toxicity of materials used in aircraft interiors. Manufacturers are investing in innovative resin systems and fire-resistant coatings to comply with these standards. - Rising Adoption of Composite and Sandwich Structures

Advanced sandwich panel structures, composed of honeycomb cores and fiber-reinforced skins, are increasingly used for their superior strength-to-weight ratio. These materials also allow for greater design flexibility and longer service life, reducing maintenance costs. - Growing Maintenance, Repair, and Overhaul (MRO) Activities

The global aircraft MRO industry’s growth is boosting demand for retrofit and replacement floor panels. Airlines are upgrading existing fleets with lighter and more durable materials to extend aircraft lifespan and improve cabin aesthetics.

Market Segmentation

- By Material Type:

- Nomex Honeycomb

- Aluminum Honeycomb

- Carbon Fiber Reinforced Plastics (CFRP)

- Glass Fiber Reinforced Plastics (GFRP)

- By Aircraft Type:

- Commercial Aircraft

- Business Jets

- Regional Aircraft

- Military Aircraft

- By End Use:

- OEM (Original Equipment Manufacturer)

- Aftermarket (Maintenance, Repair, and Overhaul)

Regional Insights

- North America:

Dominates the global market due to the strong presence of major aircraft manufacturers like Boeing and Bombardier, coupled with ongoing fleet modernization projects. - Europe:

A key hub for aerospace innovation, Europe leads in lightweight composite technology, with Airbus and numerous Tier-1 suppliers driving product advancements. - Asia-Pacific:

Emerging as the fastest-growing region, supported by rapid aviation growth in China, India, Japan, and South Korea. Increasing regional airline operations and aircraft production are fueling market expansion. - Middle East and Latin America:

Witnessing steady growth due to rising investments in airport infrastructure and expanding regional aircraft fleets for both commercial and defense applications.

Checkout Now to Access Industry Insights:

https://www.futuremarketinsights.com/checkout/5349

Competitive Landscape

Key players in the global Aircraft Floor Panels Market include:

The Gill Corporation, Collins Aerospace, Triumph Group, Aim Altitude, Euro-Composites S.A., Zodiac Aerospace (Safran Group), and Nordam Group.

These companies focus on developing next-generation composite floor panels that combine lightweight construction, fire protection, and high structural integrity. Strategic collaborations with aircraft OEMs and long-term supply contracts remain key competitive strategies.

Technological Innovations

- Integration of carbon fiber and thermoplastic composites for recyclable and repairable panel designs.

- Development of nano-reinforced honeycomb cores to enhance stiffness and impact resistance.

- Use of 3D printing and automated fiber placement (AFP) for efficient production of custom panel geometries.

- Implementation of AI-based predictive maintenance for early fault detection and lifecycle optimization.

Future Outlook

The Aircraft Floor Panels Market is set for robust growth through 2035, supported by airline fleet expansion, material innovation, and the aviation industry’s sustainability goals. As aerospace manufacturers shift toward fully composite airframes and recyclable materials, floor panel suppliers are expected to play a pivotal role in advancing aircraft efficiency and passenger safety.

Sustained investments in lightweight structures, fire-retardant resins, and next-generation manufacturing processes will ensure that the market continues to evolve in line with the industry’s technological progress.