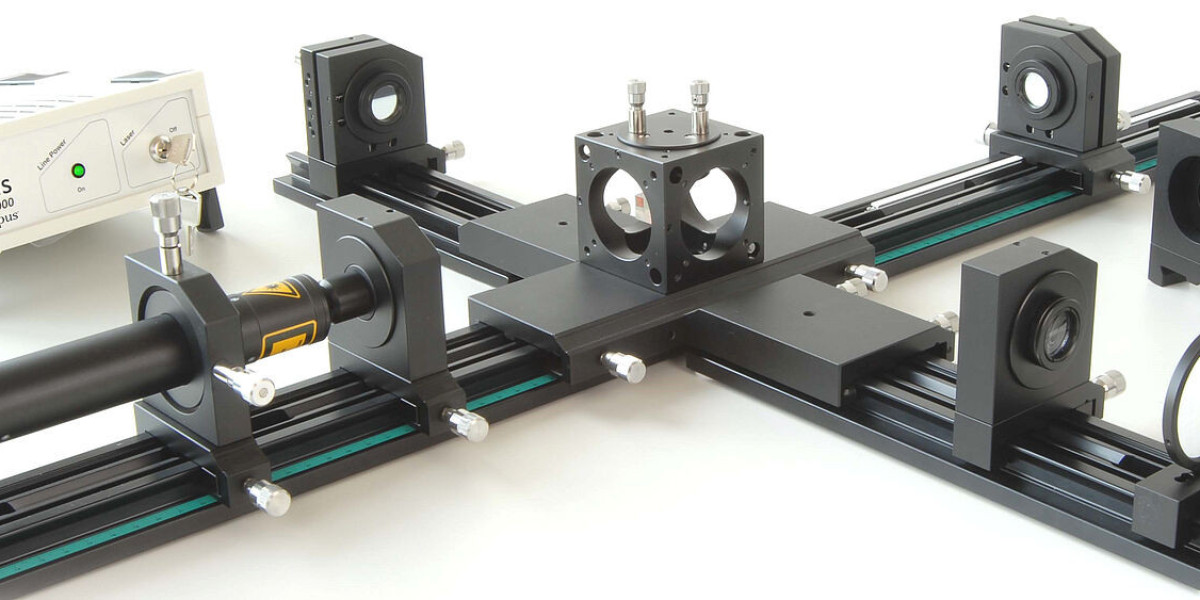

Laser welding has revolutionized the world of metal joining, offering unmatched precision, speed, and strength. At LaserChina, we specialize in crafting laser beam welders that deliver “molting beams with perfection.” These machines combine cutting-edge optics and thermal control, ensuring clean, high-quality welds with minimal distortion. Whether you are in automotive, aerospace, medical, or electronics manufacturing, our laser beam welders guarantee performance that meets industrial demands.

Understanding Laser Beam Welding

Laser beam welding (LBW) uses a concentrated beam of light to melt and fuse metal parts. The laser’s high energy density creates a narrow, deep weld zone with exceptional accuracy. Unlike traditional welding methods, it requires no filler material, reduces post-processing, and ensures aesthetic, durable joints.

This precision process is ideal for microscopic components as well as thick metal sheets, making it one of the most versatile welding technologies available today.

Specifications of LaserChina Laser Beam Welders

At LaserChina, we design our welders for performance, reliability, and user control. Here are the core specifications:

Laser Power Range: 100W – 6000W (adjustable based on application)

Wavelength: 1064 nm for maximum absorption in metal surfaces

Beam Quality (M²): ≤ 1.2 for precision welding

Positioning Accuracy: ±0.02 mm

Cooling System: Water-cooled for consistent performance

Operating Modes: Continuous and pulsed laser operation

Interface: Smart digital display with real-time monitoring

These technical features ensure smooth operation and superior results, even in demanding industrial environments.

Applications of Laser Beam Welders

Laser beam welders from LaserChina are used across a wide range of industries due to their adaptability and clean operation.

1. Automotive Industry

Used for precision joining of car bodies, transmission components, and battery systems in electric vehicles.

2. Aerospace and Defense

Ideal for welding titanium, aluminum, and nickel alloys where reliability and light weight are critical.

3. Medical Devices

Used for creating intricate welds on stainless steel and titanium surgical tools, ensuring sterilization-friendly joints.

4. Electronics and Micro-Components

Perfect for delicate assemblies such as sensors, connectors, and microchips.

5. Jewelry and Precision Tools

Allows seamless joining without discoloration or deformation of fine materials.

Advantages of Laser Beam Welding Technology

Laser beam welding provides several key benefits compared to conventional methods:

High Precision: Ensures consistent welds with minimal thermal distortion.

Speed and Efficiency: Faster processing reduces production time.

Clean and Contact-Free: No electrode wear, sparks, or physical contact.

Strong, Aesthetic Joints: Produces smooth and durable weld seams.

Versatility: Works with metals like steel, aluminum, copper, titanium, and more.

Automation Friendly: Easily integrates into robotic systems for mass production.

These advantages make laser welding the preferred choice for manufacturers focused on quality and efficiency.

How to Buy a Laser Beam Welder from LaserChina

Purchasing the right laser beam welder depends on your production scale, material type, and precision requirements. Here’s how to make the right choice with LaserChina:

Define Your Needs:

Identify your welding application—materials, thickness, and production volume.Consult Our Experts:

Our technical team will recommend the best model based on your requirements and workflow.Customization Options:

Choose from power configurations, automation options, and control interfaces.Request a Quotation:

Get a transparent quote with complete specifications and delivery details.After-Sales Support:

Benefit from installation assistance, operator training, and lifetime technical support.

Conclusion

LaserChina’s laser beam welders embody the art of “molting beams with perfection.” Designed for reliability, precision, and industrial excellence, they redefine welding standards across industries. If your business demands accuracy, speed, and superior joint quality, LaserChina offers the ultimate solution in laser beam welding technology.