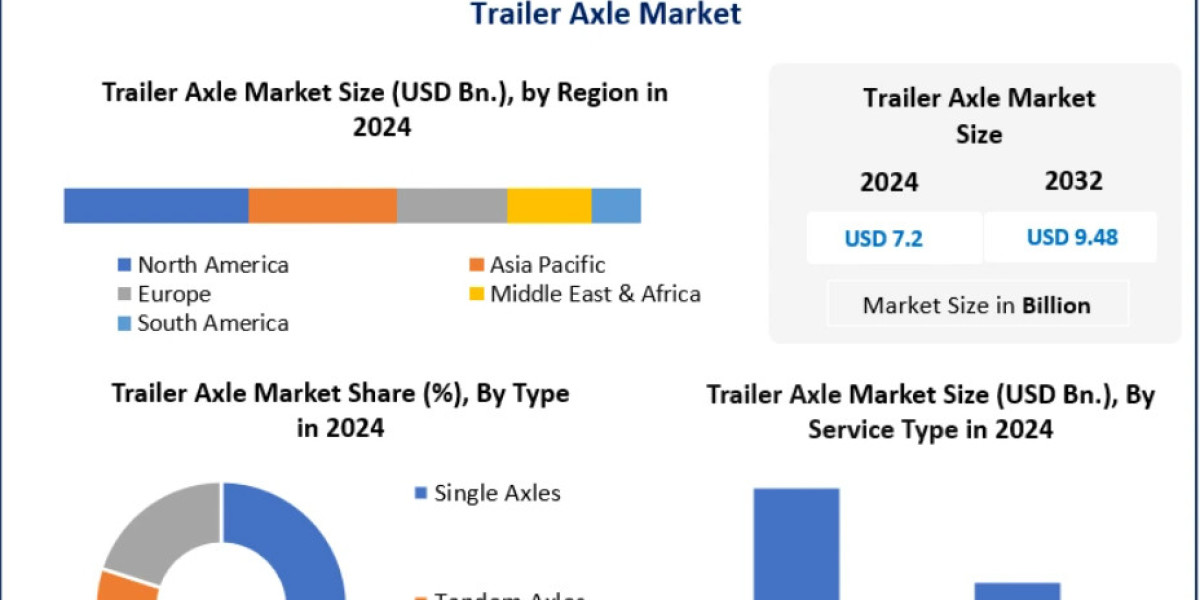

Trailer Axle Market – Global Industry Analysis and Forecast (2025–2032)

Market Size: USD 7.2 Billion (2024) | CAGR: 3.5% | Forecast Value: USD 9.48 Billion (2032)

Trailer Axle Market Overview

The global Trailer Axle Market is projected to grow from USD 7.2 billion in 2024 to nearly USD 9.48 billion by 2032, expanding at a CAGR of 3.5%. Trailer axles are essential components in heavy and light trailers, offering stability, load-bearing strength, and efficient towing capabilities. Increasing demand for lightweight, durable, and fuel-efficient transportation components is driving the adoption of innovative axle technologies across logistics, construction, agriculture, and manufacturing industries.

An axle functions as the central shaft for rotating wheels or gears, enabling vehicle movement and supporting its load. In modern trailer design, axles may either rotate with the wheels or remain fixed, depending on application type and weight requirements. The growing utilization of tandem and multi-axle configurations in heavy-duty trailers has enhanced load capacity and vehicle safety, reinforcing the global demand for high-performance trailer axles.

Rising urbanization, industrial expansion, and cross-border logistics are further augmenting the market growth. Moreover, the shift toward smart load management systems and lightweight material innovation—including aluminum, magnesium, and glass-fiber-reinforced polymers (GFRP)—is transforming axle manufacturing to meet fuel-efficiency goals and regulatory standards.

► Download a Free Sample Report Today:https://www.maximizemarketresearch.com/request-sample/83234/

Trailer Axle Market Dynamics

Key Drivers

Surging Demand from Automotive and Construction Industries

Rapid growth in automobile manufacturing and infrastructure development worldwide is fueling the need for heavy-duty and medium-duty trailers. The construction industry, projected to reach USD 15 trillion by 2029, presents substantial opportunities for trailer manufacturers and, consequently, axle producers.Shift Toward Lightweight and Fuel-Efficient Designs

To meet global emission norms and fuel economy regulations, manufacturers are focusing on lightweight axle assemblies using materials like aluminum and composite alloys, reducing overall vehicle mass without compromising durability. This trend enhances fleet efficiency and reduces operational costs.Rising Demand in Emerging Economies

Developing markets in Latin America, China, and Russia are witnessing strong demand for freight transportation and infrastructure expansion. These regions present significant potential for heavy-duty trailer axles over the forecast period.

Key Restraints

Volatility in Raw Material Prices: Fluctuations in the cost of steel, aluminum, and carbon composites impact production costs and profit margins for axle manufacturers.

Maintenance and Durability Challenges: The constant wear-and-tear of trailer axles under heavy loads necessitates frequent maintenance, influencing lifecycle costs.

Market Segmentation Analysis

By Type

Tandem Axles dominated the market in 2024 due to their superior load distribution and stability. Widely used in flatbeds, tankers, and refrigerated trailers, tandem axles ensure operational safety and reliability in long-haul freight and construction logistics.

Single Axles serve lightweight and utility trailers, while three or more axles cater to specialized heavy-load transportation.

By Capacity

The 15,000–25,000 lbs segment held the largest share in 2024. This capacity range provides optimal versatility across multiple trailer types—dry van, tanker, and flatbed—balancing strength and cost efficiency.

By Application

Flatbed and Dry Van Trailers lead the segment due to high freight movement across industrial and logistics applications.

Refrigerated and Tanker Trailers are gaining traction owing to rising demand in food transport, chemicals, and liquid logistics sectors.

By Service Type

The OEM segment dominates, supported by increased trailer production and fleet modernization programs.

The Aftermarket is expanding steadily due to the need for axle replacement, maintenance, and upgrades.

By Axle Technology

Mechanical Axles currently account for the largest market share; however, Electric and Hybrid Axles are gaining importance as the industry transitions toward sustainable mobility solutions and electric trailer systems.

► Download a Free Sample Report Today:https://www.maximizemarketresearch.com/request-sample/83234/

Regional Insights

North America

The region continues to be a major market for trailer axles, driven by high demand from logistics, agriculture, and construction sectors. The U.S. alone is valued at USD 1.7 billion, with stable replacement demand and advanced axle technologies from leading players such as DexKo Global and Hendrickson.

Europe

Europe’s trailer axle market is characterized by robust manufacturing activity and strict environmental regulations. Countries like Germany and France are promoting lightweight materials and electric axle integration to enhance fuel efficiency and reduce emissions.

Asia-Pacific

The APAC region is expected to experience substantial growth, led by China, India, and Japan. Rapid industrialization, growth in e-commerce logistics, and government investments in infrastructure are fueling trailer production. China is forecasted to grow at a 6.4% CAGR, reaching USD 1.7 billion by 2030.

Latin America

Latin America, particularly Brazil, is emerging as a key growth region. Expanding construction activities and agricultural exports are driving the demand for heavy-duty trailers and axle systems.

Middle East & Africa

Steady infrastructure development and the expansion of trade routes through GCC countries are supporting demand for durable trailer axles designed for long-haul and high-temperature environments.

Competitive Landscape

The Trailer Axle Market is moderately consolidated, with key manufacturers focusing on innovation, partnerships, and regional expansion to strengthen their market presence. Companies are investing in R&D for advanced axle systems, including electric and hybrid models, to meet evolving mobility standards.

Key Players Include:

BPW Group

DexKo Global Inc.

Meritor, Inc.

Hendrickson Corporation

FUWA K Hitch

JOST Axle Systems

SAF-HOLLAND GmbH

Schmitz Cargobull AG

York Transport Equipment (Asia) Pte Ltd

Shandong Huayue

These companies are prioritizing sustainability, modular design, and digital axle diagnostics to enhance efficiency and product longevity.

Future Outlook

The Trailer Axle Market is set for steady, innovation-led growth as the global transportation industry transitions toward sustainability and digitalization. Integration of electric powertrains, IoT-enabled axle monitoring, and lightweight materials will define the next generation of trailer axle systems.

Emerging economies, particularly in Asia-Pacific and Latin America, will play a pivotal role in driving market demand, supported by robust construction activity, expanding logistics networks, and increasing industrial output.

Conclusion

The Trailer Axle Market is evolving rapidly, influenced by the twin imperatives of efficiency and sustainability. As fleets modernize and global freight activity expands, trailer axle manufacturers must align with new technologies and materials to maintain competitiveness. Continuous innovation in design, weight optimization, and electric integration will ensure that trailer axles remain central to the evolution of global transport systems through 2032.