Traditional methods of rust removal—such as chemical treatments, sanding, or abrasive blasting—often require significant effort, time, and resources, while sometimes damaging the underlying metal. The laser rust removal machine emerges as a modern, precise solution that addresses these challenges while offering controlled and environmentally friendly rust elimination.

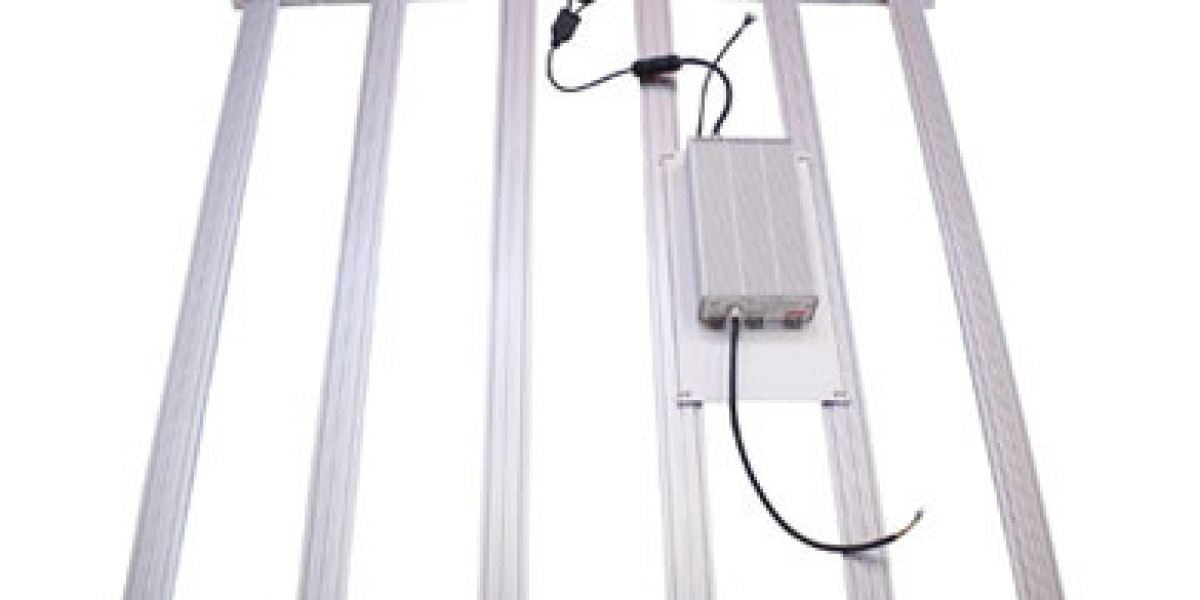

At its core, a laser rust removal machine uses high-energy laser beams to target and remove rust and oxidation layers from metal surfaces. This process relies on the principle of laser ablation, where the focused energy rapidly heats and vaporizes corrosion without affecting the metal beneath. The precision of laser cleaning allows operators to target even intricate shapes and hard-to-reach areas, making it particularly valuable in automotive restoration, industrial equipment maintenance, and fine metalwork.

Unlike conventional rust removal methods, laser cleaning does not involve harmful chemicals. This makes it a cleaner alternative for workplaces and home environments. Operators can perform rust removal with minimal safety concerns related to toxic residues, making it suitable for industries with strict environmental regulations. Additionally, laser rust removal machines can significantly reduce the preparation and post-processing time compared to manual sanding or chemical treatments.

The efficiency of laser rust removal machines extends beyond just removing rust. They also help prepare surfaces for further treatment such as painting, coating, or welding. By producing a clean, oxidation-free surface, the machine ensures stronger adhesion of protective coatings, contributing to longer-lasting results. This ability to simultaneously clean and prepare metal surfaces makes laser rust removal an essential tool for industrial maintenance programs.

In terms of operation, the process begins with calibrating the laser according to the material type and thickness of the corrosion. The operator guides the laser head over the affected surface, allowing the beam to selectively vaporize rust layers. Advanced machines come equipped with adjustable settings, enabling fine control over laser intensity and scanning speed. These settings are crucial for ensuring that delicate components or thin metal sheets are not damaged during cleaning.

Laser rust removal is also highly repeatable, which is particularly beneficial for industries requiring consistent surface quality. For example, aerospace components, precision machinery, and automotive parts often demand strict standards for surface finish. Manual methods, by contrast, are prone to variability, depending on the skill and endurance of the operator. The automation and consistency of laser cleaning help maintain uniform results across multiple components, improving overall productivity.

From an economic standpoint, investing in a laser rust removal machine can lead to long-term savings. Reduced labor, minimized material waste, and faster turnaround times translate into lower operational costs. While the initial investment may be higher than traditional tools, the return on investment becomes apparent through increased efficiency and decreased downtime. Businesses engaged in large-scale maintenance, manufacturing, or restoration projects often find that laser rust removal machines pay for themselves in a matter of months.

Another aspect that makes laser rust removal appealing is its adaptability to various metals. Whether dealing with steel, iron, aluminum, or alloys, operators can adjust the machine settings to target rust without affecting the base material. This flexibility allows one machine to handle multiple tasks, from cleaning structural steel in construction projects to restoring delicate antique items or industrial machinery.

Maintenance of laser rust removal machines is straightforward, requiring periodic cleaning of optical components and calibration checks. Since the process avoids abrasive contact with the metal, wear and tear on the machine’s working components is minimal. This contributes to a longer operational lifespan and reduces the frequency of replacements or repairs, further enhancing cost-effectiveness.

Safety is a crucial consideration when using laser equipment. Proper protective measures such as eye protection, controlled work environments, and adherence to operating guidelines ensure safe operation. Modern machines often include built-in safety features, such as shields, interlocks, and emergency stop mechanisms, reducing risks while providing confidence to operators.

In addition to industrial applications, laser rust removal machines have found a place in hobbyist workshops, art restoration, and custom automotive projects. Enthusiasts who restore vintage cars, motorcycles, or tools appreciate the precision and control offered by laser cleaning. Unlike harsh chemicals or aggressive abrasives, the laser approach preserves the original material and intricate details, maintaining both functional and aesthetic integrity.

The environmental benefits of laser rust removal are increasingly relevant in today’s sustainability-focused world. By eliminating the need for chemical rust removers and reducing waste generated from abrasive blasting, the technology supports greener operations. It aligns with industry trends toward minimizing hazardous waste, lowering emissions, and adopting cleaner production techniques.

Overall, the laser rust removal machine represents a paradigm shift in how corrosion is managed. Its combination of precision, efficiency, safety, and environmental friendliness makes it a preferred solution across a range of applications. Whether for industrial maintenance, automotive restoration, or fine metalwork, this technology empowers operators to achieve high-quality results with less effort and reduced risk of damage.

Final Thoughts

Laser rust removal machine redefine metal restoration and maintenance, providing a precise, efficient, and environmentally responsible solution. Their adaptability across industries, consistent performance, and long-term economic benefits make them an indispensable tool for professionals and enthusiasts alike. The ability to remove rust without compromising the underlying metal ensures surfaces are restored to optimal condition, ready for further use or protection.