In recent years, fire protection engineering has undergone a major digital transformation. One crucial shift has been the adoption of remote inspection workflows, where teams collaborate digitally to review designs, validate installations, and resolve issues without physically visiting the site. This approach has become especially important for fast moving construction projects, multi site operations, and global teams. At the center of this transformation is XTEN-AV, a leading platform that enhances the capabilities of Fire System Design Software, making remote inspection smoother, faster, and more accurate.

Fire design software has redefined how inspectors, engineers, and contractors work together. Through smart automation, real time collaboration, cloud based documentation, and integrated visual tools, remote inspections can now be handled with the same accuracy and reliability as on site reviews. This blog explores how these digital tools improve inspection coordination and why they are becoming standard practice in the fire protection industry.

The Rise of Remote Inspection in Fire Protection

In traditional fire protection workflows, inspections required physical meetings at the site, printed drawings, manual verification, and multiple rounds of corrections. This process often led to delays, miscommunication, and logistical challenges. With evolving project schedules and increasing pressure to deliver faster, remote inspection capabilities have become a necessity.

Fire System Design Software now offers powerful features that allow inspectors to review layouts, hydraulic calculations, equipment placements, and code compliance remotely. By using digital tools, teams can collaborative more efficiently, resolve conflicts early, and maintain project continuity even when on site access is limited.

1. Cloud Based Access Simplifies Collaboration

Modern fire design software is cloud based, ensuring that all project data, drawings, and calculations are accessible from any location. Inspectors no longer need physical documents or local files.

Benefits include.

Real time access to updated drawings.

Availability of hydraulic reports and system schematics.

No delays caused by emailing files or version mismatches.

Easier scheduling for remote meetings and reviews.

This cloud accessibility ensures that engineers, contractors, and AHJs can collaborate on a single source of truth.

2. Real Time Design Updates Improve Communication

One of the biggest challenges in traditional inspections is design revisions. When inspectors identify issues, the design team must make corrections, update drawings, and resend files. Fire System Design Software eliminates this back and forth by allowing changes to occur in real time.

Key advantages include.

Immediate visibility of revised layouts.

Faster approval cycles.

Clear documentation of what was changed and when.

Reduced risk of outdated drawings being used on site.

This real time communication dramatically accelerates project timelines.

3. Integrated 2D and 3D Visualization Enhances Review Quality

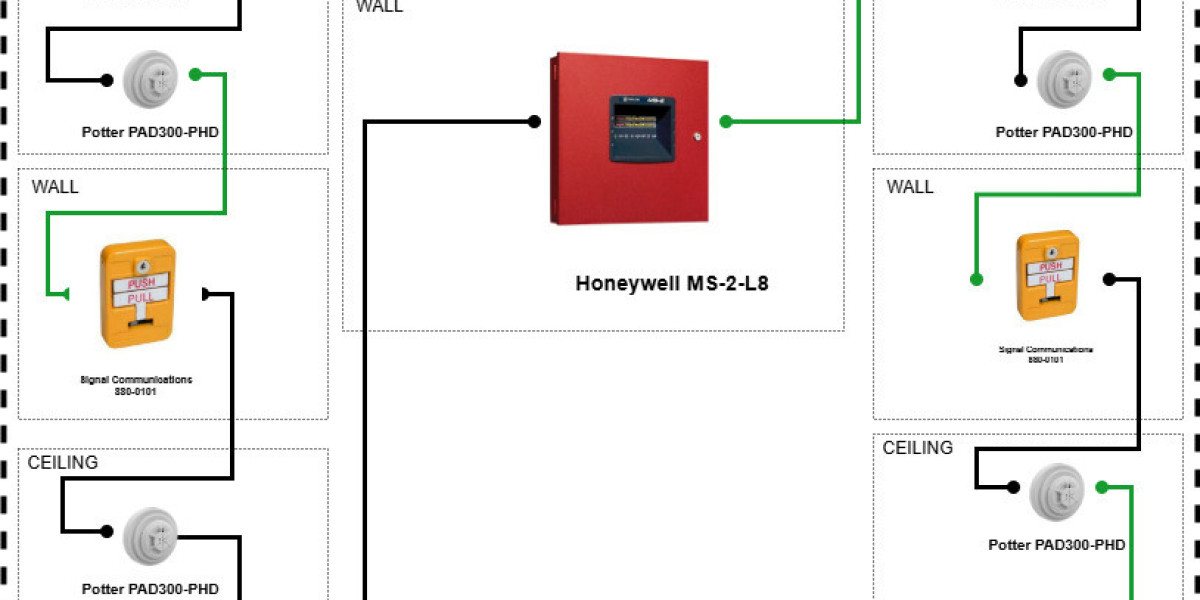

Remote inspections rely heavily on clear visuals. Fire design platforms offer advanced visualization tools that allow inspectors to view systems in both 2D and 3D formats. This improves understanding of system placement and helps teams spot issues digitally before installation begins.

These visualization tools support.

Reviewing sprinkler layouts visually for spacing compliance.

Checking pipe routing for potential clashes.

Evaluating equipment positioning in mechanical rooms.

Navigating the entire system like a virtual walkthrough.

3D visualization bridges the gap between physical site inspections and digital review sessions.

4. Automated Error Detection Reduces Manual Checking

Manual inspections often require significant time to identify spacing violations, missing sprinklers, incorrect pipe sizes, or improper slopes. Fire System Design Software automates these checks, helping inspectors spot issues instantly.

Automated checking features can identify.

Sprinkler spacing violations.

Incorrect hazard classification.

Improper pipe sizes based on hydraulic demand.

Conflicts between components and building structures.

With automated detection, remote inspections become more reliable and much faster.

5. Remote Commenting and Markup Tools Improve Communication

Modern fire design platforms include markup and commenting tools that allow inspectors to highlight issues directly on the drawings. Instead of describing a problem over a call or email, they can annotate the exact location digitally.

This delivers several advantages.

Clear instructions without ambiguity.

Permanent documentation for project records.

Faster correction cycles.

Reduced chance of miscommunication during revisions.

Markup tools make remote inspection as detailed and precise as onsite walkthroughs.

6. Seamless Integration With BIM Improves Cross Discipline Coordination

Fire System Design Software often integrates with BIM platforms like Revit. This allows inspectors to visualize fire systems within the context of the full building model.

Integration with BIM helps inspectors.

Identify clashes with HVAC, plumbing, and electrical systems.

Verify ceiling heights, wall penetrations, and room constraints.

Ensure proper spacing from obstructions.

Review fire system behavior within real architectural context.

BIM coordination eliminates guesswork during inspections and ensures designs follow real world constraints.

7. Standardized Reports Support Faster Approvals

Fire design software automatically generates professional reports such as hydraulic summaries, material lists, compliance checklists, and design notes. These reports help inspectors verify calculations and evaluate system performance without manual compilation.

Benefits of automated reports include.

Standard format for easy review.

Accurate data pulled directly from the model.

Faster approval timelines.

Reduced workload for both inspectors and designers.

Standardized reporting strengthens documentation quality and improves confidence in digital inspection results.

8. Secure Digital Records Enhance Accountability

Remote inspection workflows rely heavily on proper record keeping. Fire design tools maintain secure digital logs of all changes, comments, approvals, and revisions.

This adds value through.

Clear audit trails.

Improved documentation for compliance audits.

Long term project transparency.

Easier retrieval of past design states for comparison.

Digital records reduce disputes and ensure accountability across all project stakeholders.

9. Remote Coordination Saves Time and Travel Costs

The practical benefits of remote inspections cannot be overlooked. Fire System Design Software enables companies to save significant travel time, site visit costs, and scheduling delays.

Organizations benefit from.

Fewer onsite trips.

Faster resolution of design conflicts.

Improved availability of inspectors across multiple projects.

Greater flexibility for large or distributed teams.

Reduced downtime contributes directly to better project performance and timely delivery.

Conclusion. Fire Design Software Makes Remote Inspections Smarter and More Efficient

Remote inspection coordination has become essential for modern fire protection projects. Fire design tools accelerate workflows, eliminate geographical limitations, and support highly accurate design reviews. With cloud based access, automated checking, real time collaboration, and advanced visualization, these platforms offer unprecedented efficiency and reliability.

At the forefront of these innovations is XTEN-AV, which continues to redefine what Fire System Design Software can achieve. By improving remote inspection workflows, these tools help teams complete projects faster, reduce errors, and maintain the highest levels of safety and compliance.

As the industry evolves, remote inspection capabilities will become standard practice, and fire design software will remain the backbone that keeps teams connected, productive, and efficient.

Read more: https://social.updum.com/read-blog/29666