Wood Plastic Composite (WPC) Market – Global Industry Analysis, Trends & Forecast (2025–2032)

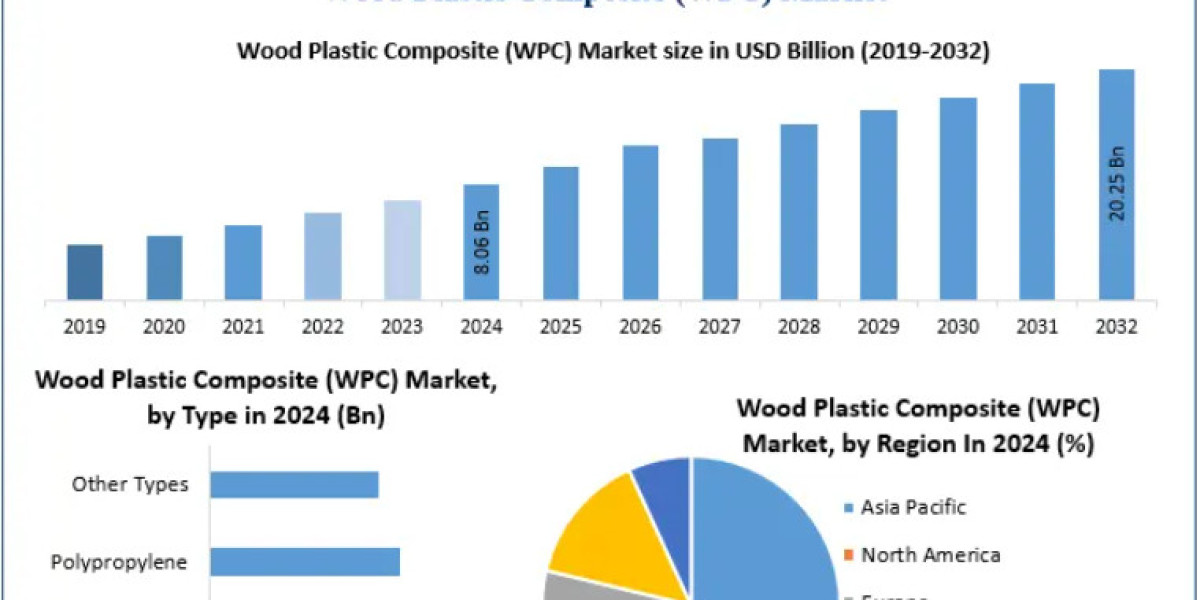

The Wood Plastic Composite (WPC) Market, valued at USD 8.06 billion in 2024, is projected to reach USD 20.25 billion by 2032, expanding at a strong CAGR of 12.2% from 2025 to 2032. As industries demand sustainable, durable, and cost-efficient alternatives to conventional wood, WPC has emerged as one of the fastest-growing engineered materials across construction, automotive, and consumer goods segments.

WPC combines wood fibers/wood flour with thermoplastics—most commonly PE, PP, PVC, and PLA—to create an advanced hybrid material that offers superior strength, low moisture content, high durability, and impressive environmental benefits. Its resistance to rot, insects, water absorption, and splintering makes it exceptionally suitable for both indoor and outdoor applications.

Market Overview

Wood Plastic Composites are manufactured by mixing heated thermoplastic resins with finely ground wood particles. Extrusion is the most commonly used production technique, although injection molding is widely applied for consumer and automotive components. WPCs can be produced using virgin or recycled plastics, positioning the material as an environmentally responsible alternative in modern manufacturing.

To enhance performance, additives such as coupling agents, UV stabilizers, colorants, foaming agents, and lubricants are incorporated. Polyethylene-based WPC dominates the market due to its balance of cost, durability, and processing efficiency.

WPC finds applications in windows, railings, flooring, fencing, decks, exterior siding, landscape materials, interior trims, and an expanding range of engineered components.

Access your free report sample — uncover the top-performing segments today:https://www.maximizemarketresearch.com/request-sample/76219/

Market Dynamics

Drivers

1. Rising Demand in Building & Construction

WPC is rapidly replacing traditional wood in decking, fencing, cladding, facade systems, and interior architecture. Its weather resistance, low maintenance, long lifecycle, and ability to support recycled content make it ideal for sustainable construction.

2. Ban on Hazardous Wood Treatment Chemicals

Global restrictions on chromium, copper, and arsenic in pressure-treated wood have accelerated the shift toward WPC, which offers safer and more eco-friendly structural alternatives.

3. Growing Use of Recycled Materials in Automotive Manufacturing

As automakers aim to reduce vehicle weight and embrace circular material usage, WPC offers benefits such as lightweight construction, improved aesthetics, and cost efficiency, driving adoption in interior trims, dashboards, parcel shelves, and load floors.

Restraints

1. Increasing Raw Material Costs

Fluctuating prices of polymers and additives create cost challenges for manufacturers, especially in regions dependent on petrochemical imports.

2. Limited Impact Resistance

Although WPC performs well in structural applications, it lacks the rigidity needed for heavy-load or high-impact conditions, restricting certain industrial uses.

Opportunities

1. Expanding Global Market with Emerging Applications

New applications in urban infrastructure, marine products, prefabricated structures, and modular interiors are creating strong growth potential.

2. Easy Processing & Customization

WPC is compatible with common thermoplastic processing methods, enabling versatile design, color variation, and product innovation.

3. Use of Recycled Materials

Manufacturers increasingly use recycled plastics and reclaimed wood fibers, offering cost savings and meeting rising sustainability mandates.

Challenges

- Weight reduction while maintaining mechanical strength

- Variability in regulations related to composite wood products

- Ensuring consistent performance under varying climatic conditions

Market Segment Analysis

By Application

- Building & Construction

Dominant segment with the largest market share. Demand is driven by decking, siding, cladding, railings, and landscaping applications. - Automotive Components

Expected to grow significantly as OEMs adopt lightweight, recyclable materials. - Industrial & Consumer Goods

Includes furniture, household items, and industrial accessories. - Others

Includes marine products, pallets, and extrusion profiles.

Access your free report sample — uncover the top-performing segments today:https://www.maximizemarketresearch.com/request-sample/76219/

Regional Insights

Asia Pacific – Fastest Growing Region

Asia Pacific leads in growth due to rapid expansion of the construction, infrastructure, and industrial sectors in China, India, and Southeast Asia. Government initiatives for improved civic infrastructure and drainage systems further boost demand. Low-cost manufacturing and abundant raw materials make the region a manufacturing hub for WPC products.

Europe – Strong Demand for Recycled Materials

Stringent environmental regulations and strong sustainability objectives position Europe as a major adopter of WPC. The shift toward eco-friendly alternatives to conventional wood fuels consistent demand across Germany, France, the UK, and Italy.

North America – Mature but Strong Market

Widespread adoption in decking, fencing, and outdoor structures, combined with a large DIY segment, supports robust demand. Advances in polymer technology and strong consumer preference for durable materials contribute to market growth.

Middle East & Africa / South America

Emerging demand in residential and commercial construction, supported by urbanization and climate-resilient infrastructure development.

Competitive Landscape

The WPC market is competitive, with companies focusing on product innovation, expanded polymer blends, sustainable formulations, and architectural-grade solutions.

Key Players

- Trex Company, Inc.

- The AZEK Company

- Fiberon

- UFP Industries Inc.

- Advanced Environmental Recycling Technologies, Inc.

- TAMKO Building Products, Inc.

- CertainTeed, LLC

- Dow

- Polyplank AB

- MoistureShield

- RENOLIT SE

- Universal Forest Products, Inc.

- Seven Trust

- Beologic

- Green Dot Bioplastics Inc.

- Josef Ehrler GmbH & Co KG

- FKuR Kunstsoff GmbH

- Axion Structural Innovations LLC

- Crane Plastics

- Hardy Smith Designs Pvt. Ltd.

- Guangzhou Kindwood Co. Ltd.

- Woodmass

- Oakio Plastic Wood Building Materials Co. Ltd.

- Meghmani Group

- JELU-WERK J. Ehrler GmbH & Co. KG

- Polymera, Inc.

- Plygem Holdings Inc.

These companies compete through strategies such as R&D investments, multi-layer composite technologies, recycled content integration, and global distribution expansion.

Conclusion

The Wood Plastic Composite (WPC) Market is set for strong growth due to increasing construction activities, sustainability-driven material adoption, and rising demand from the automotive and consumer goods sectors. With its combination of durability, recyclability, design flexibility, and low maintenance, WPC stands out as a preferred material for future-ready, eco-conscious applications across global industries.